PNEUMATIC EQUIPMENT FOR PRESS MACHINES

|

-

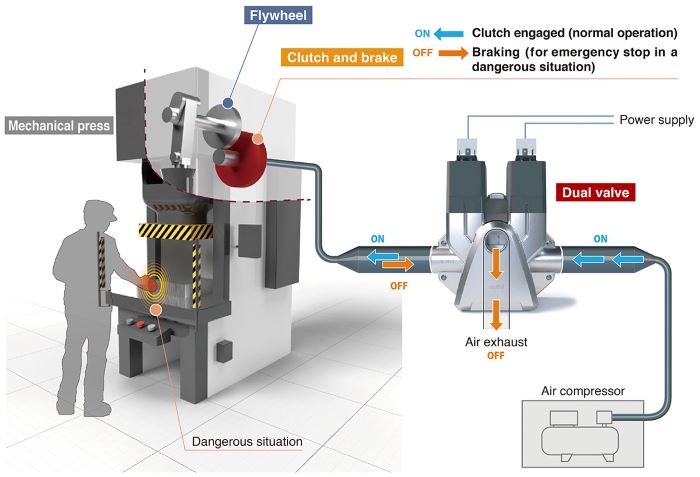

■What is a Dual Valve? Press machines are used in the processing of various parts such as automobile bodies, parts of computers and smartphones, and coins. Press machines are categorized into mechanical presses, hydraulic presses, and servo presses based on the power source used for applying pressure, and dual valves are incorporated into mechanical presses.

A mechanical press operates by converting the rotational force of a flywheel driven by a motor into linear motion through a crankshaft via a clutch, thereby moving the die up and down to process metal sheets. The dual valve is integrated into the control system of the clutch and brake, playing a crucial role in safely controlling the machine's operation. It can be considered the "heart" of the mechanical press.

-

■New Dual Valve - Model No. TX-A In recent years, the needs for dual valves in mechanical presses have been evolving. There is an increasing demand for improved basic functions such as response speed to ensure the mechanical press stops reliably and reducing residual pressure during failures to protect operators' safety. Additionally, the push towards a sustainable society has made environmental design requirements an unavoidable theme in the industrial sector.

In response to these trends, we decided to fundamentally review the current products that have been provided for about 40 years since their release in 1979. With the goal of achieving "world No.1 performance," we started developing a new product and released the new dual valve Model No. TX-A (hereinafter, TX-A) in May 2020, aiming for further safety and environmental friendliness.

The following three points were emphasized during planning and development:

1. Improved Safety

We aimed for the best performance among products of the same size and price range by ensuring faster and safer operation. Mechanical presses use pneumatic pressure to control the power transmission from the clutch, and in emergencies, it is required to quickly exhaust the pneumatic pressure to cut off the power transmission from the clutch. The new model, TX-A, features an evolved unique L-shaped cross-flow passage structure from the traditional cross-flow passage structure. This allows for quicker stopping of the mechanical press in emergencies, such as a failure of one side of the valve, significantly improving operator safety.

2. Environmentally Friendly Design

The TX-A actively adopts plastic molded parts and aluminum die-cast parts, reducing the number of parts and achieving about 22% weight reduction and about 41.4% resource savings. Additionally, by optimally designing major mechanical elements (coils, pilot valves, main valves) as a single unit, power consumption is reduced by about 50%, contributing to energy saving in the end user's manufacturing site. As a result, the TX-A achieves an approximate 51.7% reduction in LC-CO2*1 compared to previous products.

3. Balancing Design and Function

While traditional dual valves prioritized function and performance, the TX-A focuses not only on function and performance but also on a sophisticated new design. Our product color "Green Gold" has been widely recognized as a symbol of "safety and high quality," but in consideration of environmental impact, the design of the TX-A has been renewed. With the cooperation of designers with rich experience in the industrial product field and Azbil's Design Management Department, we achieved a design that expresses novelty, precision, and robustness. The new product design also visually represents the redundancy of the dual valve configuration and the cross-flow structure, embodying the principle that "form follows function." It has been highly evaluated from various quarters, winning the Good Design Award in 2021.

*1: LC-CO2 (Life Cycle CO2) The total amount of carbon (CO2) emitted throughout the product's life cycle (planning, production, operation, dismantling).