LUBRICATION SYSTEMS FOR MACHINE TOOLS

|

-

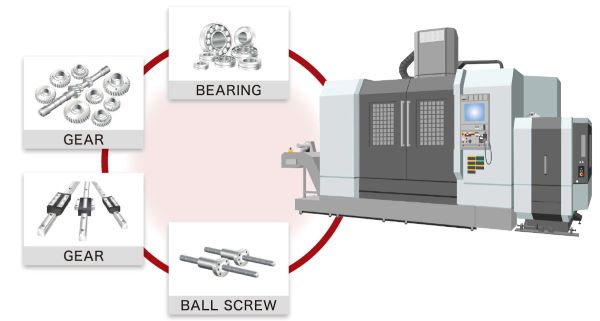

■Importance of Lubrication in Machine Tools Machine tools, such as NC lathes, machining centers, and multi-tasking machines, use mechanical components like bearings, gears, linear motion units, and ball screws. When these mechanical components move, friction occurs at the metal contact surfaces, resulting in frictional heat and wear. Lubrication with grease or oil is used to suppress this frictional heat and reduce the wear of mechanical components. Lubrication plays a very important role in ensuring the stable operation of machinery.

In recent years, the trend towards faster and more precise cutting processes has made the temperature rise of mechanical components a significant challenge. Oil lubrication is more effective than grease in suppressing heat generation, making it especially suitable for lubricating high-speed rotating bearings. Among oil lubrication systems, using the CPL MICRONLUB Lubrication Unit allows for even more effective and optimal lubrication.

-

■Four Unique Features of the CPL MICRONLUB Lubrication Unit The CPL MICRONLUB Lubrication Unit pulverizes oil to a particle size of about 2μm using the power of compressed air, generating and controlling a fog mixed with compressed air. It has the following four unique features:

1. Effective Heat Suppression Through Optimal Oil Amount Lubrication

Lubrication involves forming an oil film on the metal contact surfaces of mechanical components to reduce frictional heat and wear. Excessive oil results in a thicker oil film, increasing heat generation due to fluid friction. Conversely, insufficient oil results in the loss of the oil film, causing metal contact surfaces to wear. Optimal lubrication means covering the metal contact surfaces with an appropriately thick oil film. The CPL MICRONLUB Lubrication Unit controls micro amounts of oil by converting it into fog, supplying the appropriate amount of oil to the metal contact surfaces. Additionally, the cooling effect of compressed air helps prevent the temperature rise of mechanical components, improving the performance and stability of the machinery.

2. Intermittent Operation and Energy Saving Effect Through High-Speed Fog Transport

The CPL MICRONLUB Lubrication Unit can transport oil at a high speed equivalent to a flow velocity of 10m/sec within the piping by converting it into fog. This allows for supplying the necessary amount of fog at the required timing according to the movement of mechanical components, and the lubrication unit can stop when the mechanical components are not in motion. By shortening the operating time of the lubrication unit, the consumption of air and oil is reduced, contributing to the reduction of power consumption and CO2 emissions.

3. Longer Machine Life Through Oil Purification

During the fog generation process, fog particles larger than 2μm and foreign substances are filtered out. This prevents foreign substances from adhering to the mechanical components, extending the life of the mechanical components.

4. Reduced Machine Costs Through Simple Piping

Since the fog can be installed with the same piping construction as compressed air piping, the piping structure is simplified, leading to reduced machine costs compared to other oil lubrication systems.

-

■Support for Selection, Setting, and Design of Lubrication Units We provide support for your selection, setting, and design tasks by consolidating the following information (1 to 4) into a lubrication specification document.

1. Equipment Selection for Lubrication

Units We propose the optimal lubrication unit according to the type of your machine tools and the specifications of mechanical components (such as bearing rotation speed, gear pitch diameter, etc.).

2. Support for Setting Operating Conditions of Lubrication Devices

We propose operating conditions (such as pressure settings to be used, lubrication oil amount setting conditions, etc.) according to the specifications of mechanical components.

3. Proposal of Fog Supply Nozzle Conditions and Piping Layout

Utilizing the abundant experience of a specialized manufacturer, we propose nozzle conditions (such as nozzle diameter, quantity, and placement) and piping layout suitable for fog.

4. Usage Instructions for Lubrication Units

We explain the usage instructions and precautions for using the lubrication units.

For other inquiries related to lubrication or evaluation samples, please contact us through the form below or reach out to our sales representatives.