CUSTOM PRODUCTS

Custom Products Tailored to Your Needs

Custom Products Tailored to Your Needs

We listen to your challenges, design and manufacture optimal products, and deliver high-quality solutions.

Custom Products Introduction Process

STEP1:

Hearing and Requirement Definition

We listen carefully to your needs, including specifications and applications, and define specific requirements.

STEP2:

Concept Design

Based on our technical expertise,

our development team designs the product.

STEP3:

Prototype Production

We evaluate the performance of the prototype in our facilities and have

it verified in your application.

STEP4:

Detailed Design

Based on the evaluation results of

the prototype, we adjust and redesign specifications to maximize performance in your application.

STEP5:

Production

We procure materials and carry out assembly and quality inspection in our factory to achieve QCD (Quality, Cost, Delivery) that satisfies our customers.

STEP6:

Introduction

We conclude the trade contract and start providing the products.

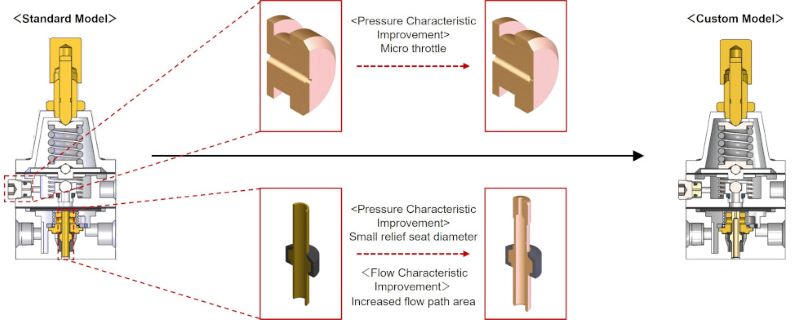

Case Study: Precision Regulator

Case Study: Precision Regulator

●Customer Request

We need a regulator with excellent pressure characteristics within the required application range.

●Design Requirements (Specification Requirements)

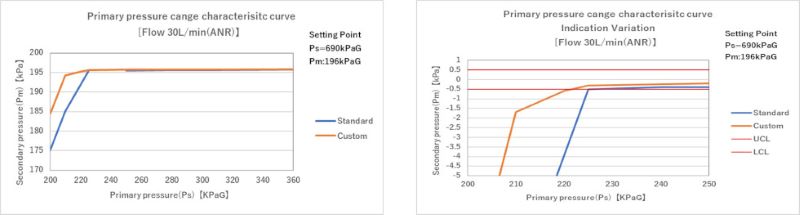

- Supply Pressure: We want to keep pressure fluctuations within ±0.5kPaG at 0.25-0.5MPa.

- Flow Characteristics: We want to keep pressure fluctuations within ±0.5kPaG at a maximum flow rate of 100L/min(ANR).

- Pressure Reproducibility: We want to keep pressure within ±0.5kPaG even when the supply pressure is turned On/Off.

(Note: As a trade-off characteristic, relief flow/sensitivity is not required.)

●Customization Details

Customizing some parts of the standard model R42-201-20T0

●Characteristic Comparison (Pressure Characteristics)

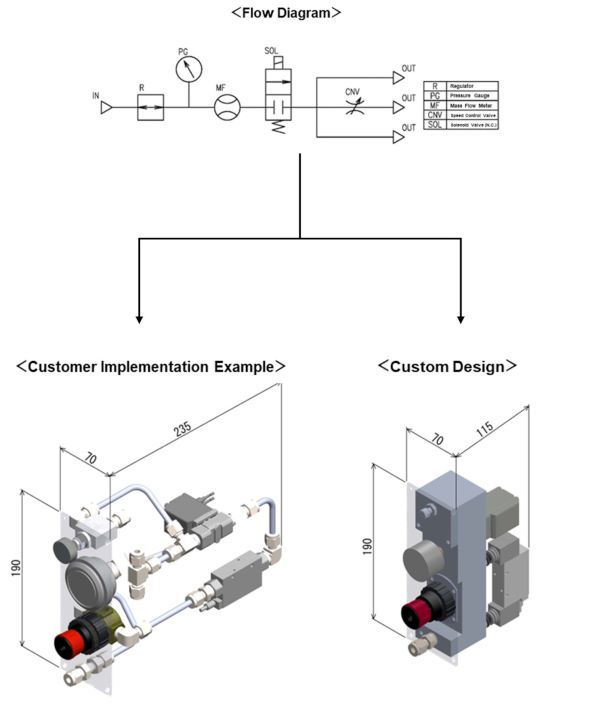

Case Study: System Equipment

Case Study: System Equipment

●Customer Request

We want to reduce the installation space for gas control equipment.

● Design Requirements (Specification Requirements)

- The characteristics of each element cannot be changed.

- The pressure supply port and mounting position on the equipment must remain unchanged.

●Customization Details

- Blockification of Flow Path

Effect: Downsizing of equipment for space-saving installation. Simplified piping design.

- Reduction of Number of Parts (Fittings: 11→4, Piping: 6→0)

Effect: Reduction of parts management costs. Shortening assembly work time. Reduction of quality risks such as gas leakage.