Technical Information

MQL semi-dry machining unit

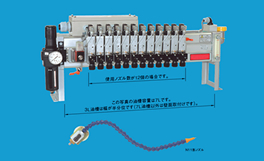

1. MINIMUM QUANTITY SPRAYING UNIT L43 SERIES

’╝łMINIMUM QUANTITY SPRAYING UNIT L43 SERIES’╝ē

Advanced MQL semi-dry machining can be introduced without any modifications or adding special devices.

Mist oil can be easily diluted or concentrated.

Spray pressure at the nozzle can be adjusted as well.

Applying a small quantity of lubricant via intermittent spray is optimal for many applications.

2. SEMI-DRY CPL LUBRICATION UNIT MCA SERIES

’╝łSEMI-DRY CPL LUBRICATION UNIT MCA SERIES’╝ē

Semi-dry CPL lubrication units are atomizers that disperse oil into fine mist, and deliver it, together with air, to a tool edge.

Cutting, grinding, drilling, tapping and other operations are performed in almost dry state, with a small amount of oil.

Machining can be performed without delivering a coolant, which not only prevents environment from contamination because of coolant spitting, but also eliminates the need in oil removal from chips and workpieces.

3. ENERGY SAVING OIL ATOMIZATION UNIT MQ4-031 SERIES

’╝łENERGY SAVING OIL ATOMIZATION UNIT MQ4-031 SERIES’╝ē

These are fog (mist) generators optimal for MQL (Minimum Quantity Lubrication) semi-dry machining.

Tool edges are lubricated by minimum quantity of the oil dispersed into fine mist.

These units can be used for drills of Žå5 mm and smaller. With a drill of Žå5 mm, oil flow rate is approx. 5 cm³/h. The units support oil flow rate to approx. 80 cm³/h, which makes possible various machining of aluminum and other materials. Due to the dual circuit of fog generation in MQ4 units, fog generation and air flow can be switched according to the tool size.

Bypass regulator in a bypass circuit supplies air to OUT side so that OUT side pressure (tool pressure) is maintained within a certain range with respect to IN port pressure.

As a result, fog with stable tool pressure can be used at different tool diameter and oil hole diameter.

Light, fine fog can easily go through a small oil hole while condensing, which is optimal for tool edge lubrication via multiple center through-holes.

WATER MIST MACHINING UNIT MW2 SERIES

1. WATER MIST SEMI-DRY LUBRICATION PUMP UNIT MW2 SERIES

’╝łWATER MIST SEMI-DRY LUBRICATION PUMP UNIT MW2 SERIES’╝ē

MW2 Series water mist semi-dry lubrication pump units intermittently discharge water and cutting oil at respective rates optimal for water mist semi-dry machining. This unit is necessary for water mist semi-dry machining.

Semi-dry machining with water particles added to oil mist works well when machining with oil mist alone is difficult.

For example, the cooling effect of water makes possible safe and clean machining when dimensional accuracy is hard to maintain because of heat release, or when oil smoke and sparks have an adverse effect on environment and safety.

In addition, the cooling power of water can suppress adhesion even in machining of aluminum and other nonferrous materials with relatively low heat release.